Well looking ahead to my retirement, I’ve now started planning a home workshop “Man cave” in my 2 story basement

8 Comments

admin

15 March 2021 - 19:28

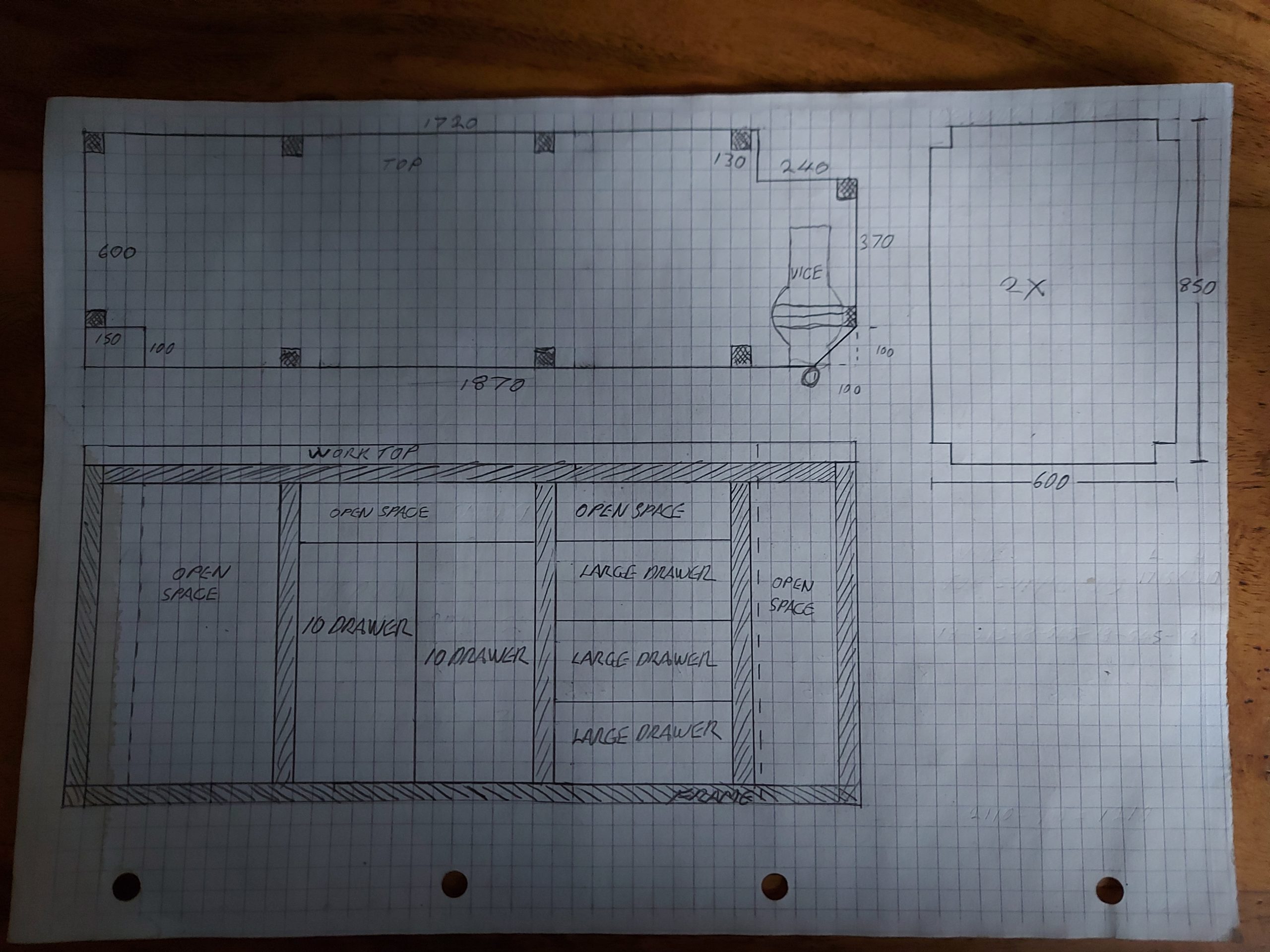

First plans done with a free CAD package

admin

28 March 2021 - 17:54

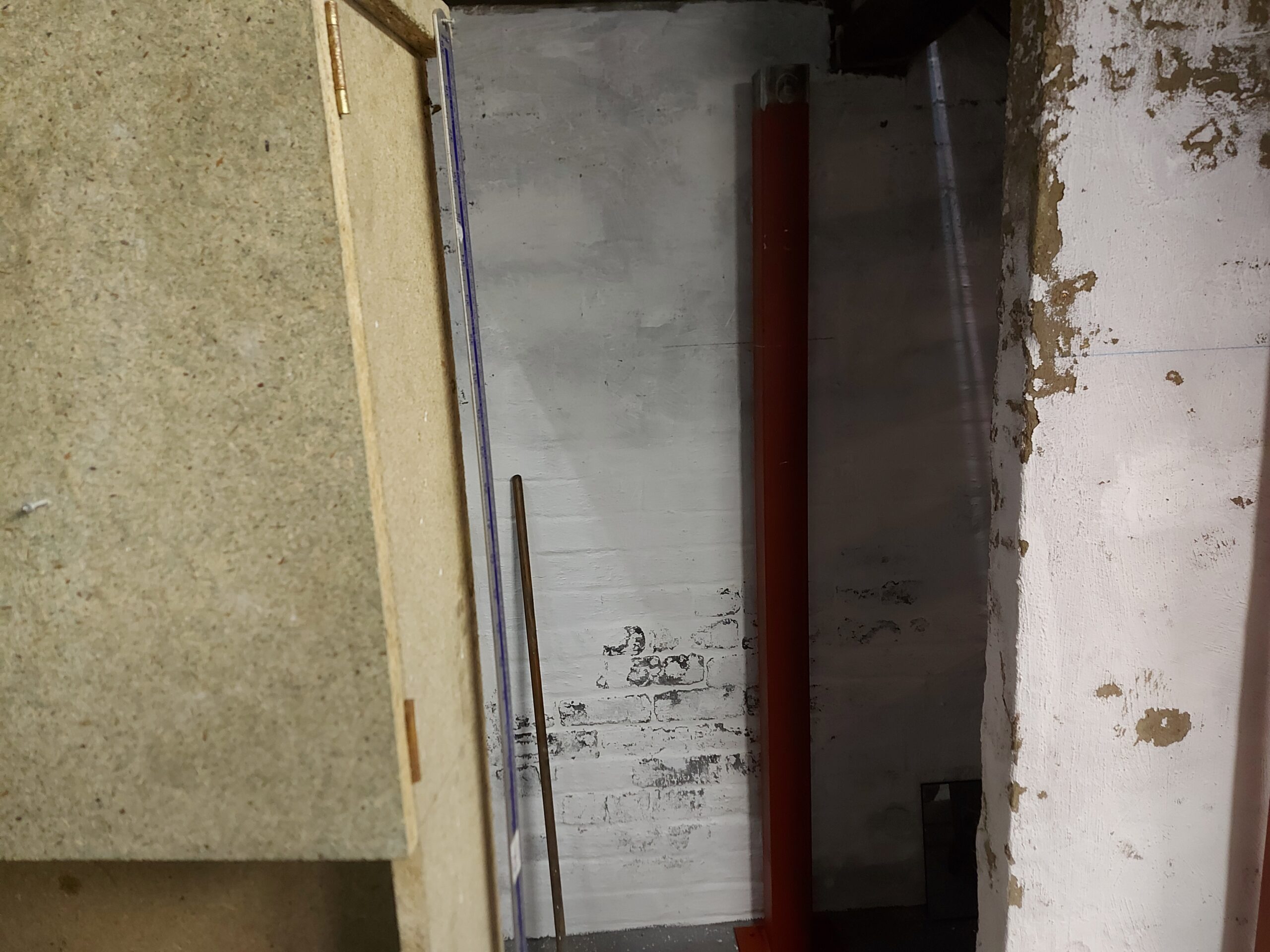

So one of the previous owners of this house put up a really Crappy mezz level floor in the cellar (A real botch job) But we used it all the same,

I’ve now started to remove the huge pillars they put in made from anything they could find ! All I can say is it looked crap but it was tough to break it down, Must have cost them a small fortune in sand/ cement to build these huge pillars, The beams don’t span the room so I had to make so Canter lever brackets to support the joists so I can remove everything including the original concrete floor “ Wish I’d done this 20 years back when I was younger,

Good Friday spent demolishing in new workshop

Looking tidy

Digging it out damed hard work in your 60s

More Digging later

Well another long couple of days spent digging meny thanks to janet my wife for her help digging all this out, Esemated about 12 tonnes in all

With a BIG thanks to my wife Janet for her help all the digging out and staires removed too, Just need the concrete in now then I can start the steel work,

Builder wasn’t happy with level so He sorted it out

Visqueen and reinforcement bars in ready for concrete pore

My mate said can you grab a piece of timber from my place on your way back we need it for shuttering OK I said but I’m in the Smart car!! So when I arrived with the timber he said look! a smart Lolly pop

I love to sit and watch others work

The plant room Under the greenhouse lol (this is were the compressor’s and blaster will live)

He wasen’t happy about the finish so he came back to flote it off

First coat of paint for main part of floor, Not done to edge as it still needs sealing to walls, But on the plus side walls be pressure washed when paint is dry, Nealy there

Sealing the edges of the concrete, Also had some sort of reaction with floor paint and concrete sealer?

Started to fill the pointing with my own form of slurry Applied with a large brush, basic idear is won’t need as much Tanking as it’s expensive stuff to use as pointing

That’s the ground floor coated, ready for damp proof slurry next

Had to have a look with a motor in there? looking good nice space.

one coat of tanking at bottom of staires, Completed now

Two coats of tanking on both these walls next white paint

Basic plan for work bench

Had this old kitchen worktop hanging around so a white benchtop should be fun to keep clean LOL

Bisley drawer units fitted and first fix on big drawers

Little more done on bench

A little painting done

Little more painting and some work on bench

Painted Bench

Drawer fronts look a little crapy so more gray paint

Drawers all painted

Got the vice in place now looking like a proper bench lol

I built this bench about 20 years back, All the top are 500×500 inlet tool panels with switches on the front,

admin

23 April 2022 - 19:29

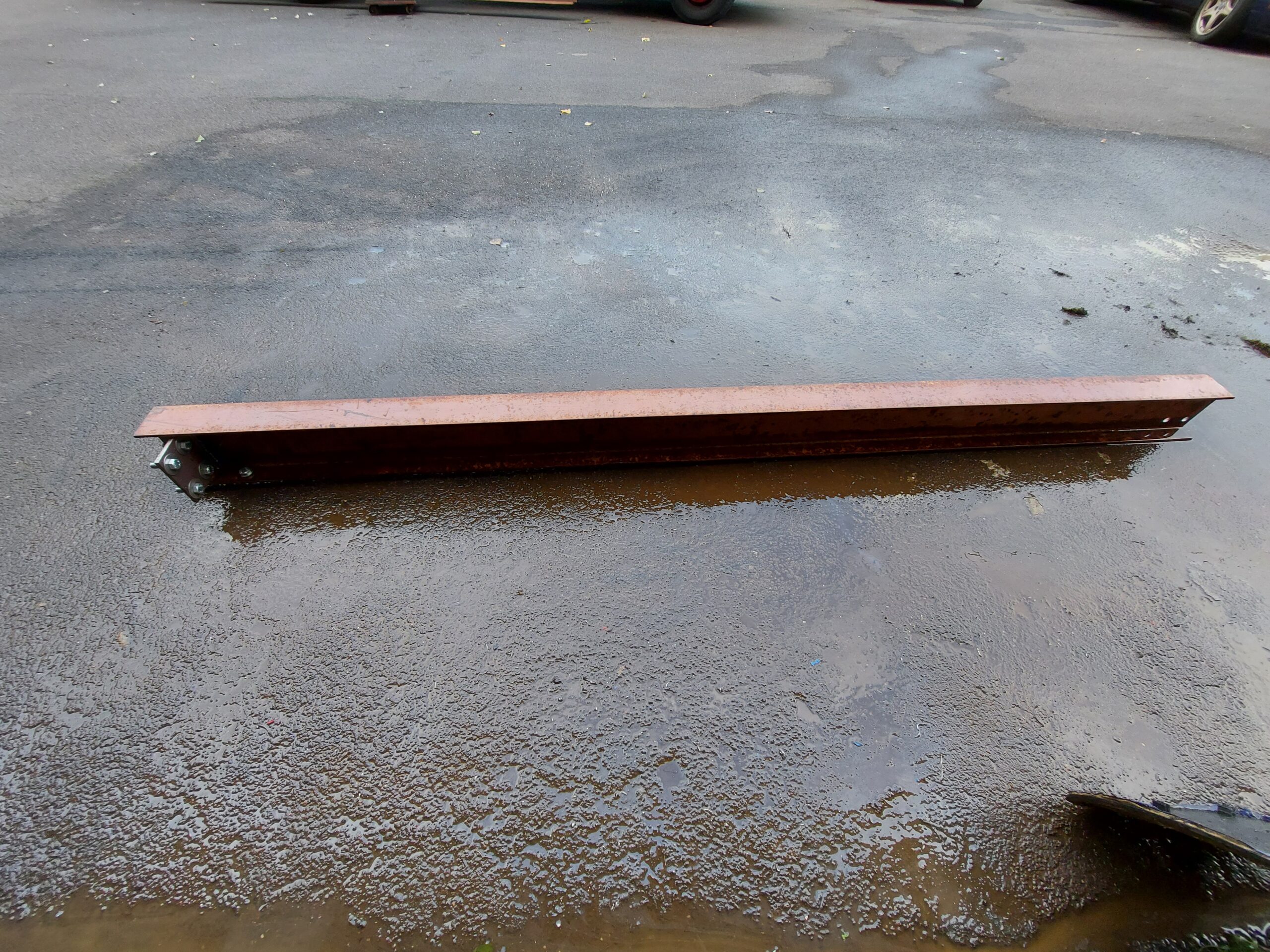

Steel Work

The Stairs

I got a fire escape about 15 years back from a local Pub/Restaurant, They’ve sat at the bottom of the garden ever since, they was for an outdoor access but now getting used inside,

Got the steel stairs off for sand blasting today (Tuesday)hopefully painting it on Thursday,

Bugger the assembled unit is 12.5mm too wide for the opening so 4 long cuts have to be done,

The gap for the staircase is 31″ Staircase is 31.5″ So I’ve decided to take 1.25″ off each Side rails making it 31″ and I will need to weld all nuts into the channel so it can be erected in place from under the stairs,

The Last long cut to do,

All the nuts welded in place,

More red oxide,

Grey Floor pain first coat

The Treads

Looks like this was built on a site! not in a factory had to mess around with every tread plate to find the only place it would fit on the side rails

The under side

Maked all with a number welded into the under side

Getting the red-lead on

The under side only needs one coat looking nice and light

Next step is 2 coats of Gray floor paint on top sides

At last the staires are in we can now get up/down without a ladder lol

Temporary position till steel mezz level goes’ in but looking like it will be perfect

admin

17 August 2022 - 18:28

Mezz Level

At last the steel as arrived, Time to start fabricating & erecting it

Got the Column steels out and cut to size

Cleaned up

Little red lead painted on

Set and Tacked on to base plates

You can fit 10m of 4×4 box in a smart car lol

Base plates fully welded on

I have a Portamig 350 I repaired this is the first time I’ve used it! it welds nice

Got some steel cut down and 10mm flanges welded holes driled and Taped out to 16mm

These steels are the backbone of the structure and need to be the first erected

admin

24 September 2022 - 20:49

Out with the Old in With the New

At last all the old Mez level is coming out

Looks like there’s some holes to brick up too,

The last joist had to be cut out,

At last it’s all out,

Tempory supports removed,

The New Steels

All cut Drilled and plates welded on just need cleaning & painting

Steels B & D make the backbone of the framework both 305×102 12×4″ in old monies

Sutch a good feeling to see the Backbone of this project in place,

All test fitted and taken down for final welding and painting

More painted steels

The last of the main structure are back

Soon as this paint is dry i can start getting the main stricture up again

admin

19 October 2022 - 22:21

Final Build time

Well my needle scaler broke again! so putting some flooring in the steel that’s already up,

It’s bean a long weekend & it realy feels like I’m getting somewere with it,

Some tempory lights till I get the LED’s

One more piece of steel up and painted, It’s definitely easier to paint them when there erected as the grey paint takes 3 days to dry,

End steel made cleaned and fitted

Joists Fitted and floor just laid on top till later

Yet another piece of steel mounted,

This short steel is one of the more complex ones, Also carries the staires, I wasen’t looking forward to doing this one but it fitted first time,

3 more cut just flanging to do,

Stock pile has gone down only one long and 4 short steels to get from this now, The end is getting near,

Need to bring Ramp home soon, Then I can cut the flooring and fix it all in place,

Nice to see the floor steels complete,

Joists all cut and a couple in,

More gray paint

A temporary platform to access the stairs again

Ran out of CO2 so decided to bring these half done upwrights home and drill them into place, They need tops welding on cleaning and painting,

At last all the steels are cut, Welded & drilled

Get this little lot erected in the morning,

I can now cut the flooring

Floor finished at last, Time to start on fitting the place out, A bit more paint

Workshop W C approx latout

So that’s it all the steelwork & floor finished Time to start moveing in,

admin

12 November 2022 - 19:58

Ramp Time

Ramp in Old workshop

In Position

Recomissoned and tested to top limit,

Just needs bolting down now

admin

6 December 2022 - 22:08

Old workshop starting to empty

Had a bad day getting the Carrera down!

It came down and rolled my twin set compressor over a couple of times made a fare old mess of it,

After much trouble getting it out, It’s home,

A good friend of mine Richard came round helped me for the day still jet lagged from his Holiday in America, We got so much done it was fantastic, Got the Carrera onto to first floor, and we grabbed a load of gear from the old unit too

Getting the racking up

Some of the tools and high level storage shelving

Got to find some were for about ten time this little lot

8 Comments

admin

15 March 2021 - 19:28First plans done with a free CAD package

admin

28 March 2021 - 17:54So one of the previous owners of this house put up a really Crappy mezz level floor in the cellar (A real botch job) But we used it all the same,

Nealy there

Nealy there

I’ve now started to remove the huge pillars they put in made from anything they could find ! All I can say is it looked crap but it was tough to break it down, Must have cost them a small fortune in sand/ cement to build these huge pillars, The beams don’t span the room so I had to make so Canter lever brackets to support the joists so I can remove everything including the original concrete floor “ Wish I’d done this 20 years back when I was younger,

Good Friday spent demolishing in new workshop

Looking tidy

Digging it out damed hard work in your 60s

More Digging later

Well another long couple of days spent digging meny thanks to janet my wife for her help digging all this out, Esemated about 12 tonnes in all

With a BIG thanks to my wife Janet for her help all the digging out and staires removed too, Just need the concrete in now then I can start the steel work,

Builder wasn’t happy with level so He sorted it out

Visqueen and reinforcement bars in ready for concrete pore

My mate said can you grab a piece of timber from my place on your way back we need it for shuttering OK I said but I’m in the Smart car!! So when I arrived with the timber he said look! a smart Lolly pop

I love to sit and watch others work

The plant room Under the greenhouse lol (this is were the compressor’s and blaster will live)

He wasen’t happy about the finish so he came back to flote it off

First coat of paint for main part of floor, Not done to edge as it still needs sealing to walls, But on the plus side walls be pressure washed when paint is dry,

Sealing the edges of the concrete, Also had some sort of reaction with floor paint and concrete sealer?

Started to fill the pointing with my own form of slurry Applied with a large brush, basic idear is won’t need as much Tanking as it’s expensive stuff to use as pointing

That’s the ground floor coated, ready for damp proof slurry next

Had to have a look with a motor in there? looking good nice space.

one coat of tanking at bottom of staires, Completed now

Two coats of tanking on both these walls next white paint

Basic plan for work bench

Had this old kitchen worktop hanging around so a white benchtop should be fun to keep clean LOL

Bisley drawer units fitted and first fix on big drawers

Little more done on bench

A little painting done

Little more painting and some work on bench

Painted Bench

Drawer fronts look a little crapy so more gray paint

Drawers all painted

Got the vice in place now looking like a proper bench lol

I built this bench about 20 years back, All the top are 500×500 inlet tool panels with switches on the front,

admin

23 April 2022 - 19:29The Stairs

I got a fire escape about 15 years back from a local Pub/Restaurant, They’ve sat at the bottom of the garden ever since, they was for an outdoor access but now getting used inside,

Got the steel stairs off for sand blasting today (Tuesday)hopefully painting it on Thursday,

Bugger the assembled unit is 12.5mm too wide for the opening so 4 long cuts have to be done,

The gap for the staircase is 31″ Staircase is 31.5″ So I’ve decided to take 1.25″ off each Side rails making it 31″ and I will need to weld all nuts into the channel so it can be erected in place from under the stairs,

The Last long cut to do,

All the nuts welded in place,

More red oxide,

Grey Floor pain first coat

Looks like this was built on a site! not in a factory had to mess around with every tread plate to find the only place it would fit on the side rails

The under side

Maked all with a number welded into the under side

Getting the red-lead on

The under side only needs one coat looking nice and light

Next step is 2 coats of Gray floor paint on top sides

At last the staires are in we can now get up/down without a ladder lol

Temporary position till steel mezz level goes’ in but looking like it will be perfect

admin

17 August 2022 - 18:28At last the steel as arrived, Time to start fabricating & erecting it

Got the Column steels out and cut to size

Cleaned up

Little red lead painted on

Set and Tacked on to base plates

You can fit 10m of 4×4 box in a smart car lol

Base plates fully welded on

I have a Portamig 350 I repaired this is the first time I’ve used it! it welds nice

Got some steel cut down and 10mm flanges welded holes driled and Taped out to 16mm

These steels are the backbone of the structure and need to be the first erected

admin

24 September 2022 - 20:49At last all the old Mez level is coming out

Looks like there’s some holes to brick up too,

The last joist had to be cut out,

At last it’s all out,

Tempory supports removed,

All cut Drilled and plates welded on just need cleaning & painting

Steels B & D make the backbone of the framework both 305×102 12×4″ in old monies

Sutch a good feeling to see the Backbone of this project in place,

All test fitted and taken down for final welding and painting

More painted steels

The last of the main structure are back

Soon as this paint is dry i can start getting the main stricture up again

admin

19 October 2022 - 22:21Well my needle scaler broke again! so putting some flooring in the steel that’s already up,

It’s bean a long weekend & it realy feels like I’m getting somewere with it,

Some tempory lights till I get the LED’s

One more piece of steel up and painted, It’s definitely easier to paint them when there erected as the grey paint takes 3 days to dry,

End steel made cleaned and fitted

Joists Fitted and floor just laid on top till later

Yet another piece of steel mounted,

This short steel is one of the more complex ones, Also carries the staires, I wasen’t looking forward to doing this one but it fitted first time,

3 more cut just flanging to do,

Stock pile has gone down only one long and 4 short steels to get from this now, The end is getting near,

Need to bring Ramp home soon, Then I can cut the flooring and fix it all in place,

Nice to see the floor steels complete,

Joists all cut and a couple in,

More gray paint

A temporary platform to access the stairs again

Ran out of CO2 so decided to bring these half done upwrights home and drill them into place, They need tops welding on cleaning and painting,

At last all the steels are cut, Welded & drilled

Get this little lot erected in the morning,

I can now cut the flooring

Floor finished at last, Time to start on fitting the place out, A bit more paint

Workshop W C approx latout

So that’s it all the steelwork & floor finished Time to start moveing in,

admin

12 November 2022 - 19:58Ramp in Old workshop

In Position

Recomissoned and tested to top limit,

Just needs bolting down now

admin

6 December 2022 - 22:08Had a bad day getting the Carrera down!

It came down and rolled my twin set compressor over a couple of times made a fare old mess of it,

After much trouble getting it out, It’s home,

A good friend of mine Richard came round helped me for the day still jet lagged from his Holiday in America, We got so much done it was fantastic, Got the Carrera onto to first floor, and we grabbed a load of gear from the old unit too

Getting the racking up

Some of the tools and high level storage shelving

Got to find some were for about ten time this little lot